Composition structure of die casting machine

Author:

Dongguan Huisheng Automation Equipment Co., Ltd.

Source:

Www.gdhuisheng.cn

Release time:

2022-03-16

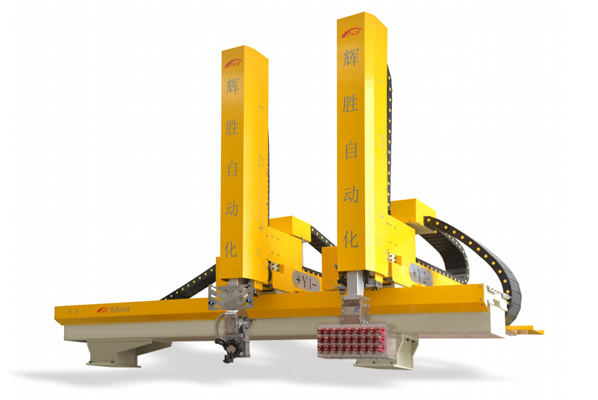

Huisheng Automation Equipment Co., Ltd. is a professional manufacturer of die-casting machinery peripheral equipment. The company was established in 1997 and is located in Dongguan City, Guangdong Province, the world manufacturing base. It was formerly known as Huisheng Precision Hardware Processing Factory. It has a history of more than 20 years and is a company integrating development, design, processing and manufacturing., Sales and service of die-casting peripheral manufacturers. Our company can become a leader in the die-casting peripheral industry. It is based on the stable and solid foundation in the past, continuously improving the technical level, and manufacturing various die-casting peripheral equipment for your company to reduce costs, reduce labor intensity of workers, and improve the rate of good products. The main products of our company areautomatic soup feeding machine,Sprayer,PICKLING MACHINES,release agent mixer,Granule machine, robot integration applications and other die-casting peripheral equipment, can be combined with various domestic and foreigndie casting machineThe connection is used together. Now let me tell you about the composition of the die casting machine:

die casting machineIt is mainly composed of clamping mechanism, injection mechanism, hydraulic system and electric control system. In addition, the die casting machine and parts and base, other devices, auxiliary devices and other parts.

1. Mold clamping mechanism

The die-casting mold is driven to close and open. When the mold is closed, it has sufficient ability to lock the mold to ensure that the mold parting surface will not expand during the injection filling process. The force of the locking mold is called the clamping force (also known as the closing force), and the unit is thousands of cattle (kN), which is the primary parameter to characterize the size of the die casting machine.

2. Shoot mechanism

Push the molten metal in the pressure chamber at the specified speed, and have enough energy to make it flow through the runner and inner gate in the mold, and then fill the mold cavity, and then maintain a certain pressure to the solidified liquid metal until the formation of die casting. After all the injection action is completed, the injection punch returns to reset.

3. Hydraulic system

Fordie casting machineThe operation provides sufficient power and energy.

4. Electrical control system

The execution action of each mechanism of the control die casting machine runs according to the predetermined program.

Key words:

Die casting machine, automatic soup feeder, sprayer, picking machine, release agent mixer, pellet machine