Application of Flexible Unit of CNC Machine Tool in Die Casting

Author:

Source:

Release time:

2024-09-30

Application of# CNC machine tool flexible unit in die casting

With the rapid development of manufacturing industry, die casting, as an efficient and mass-produced metal forming technology, has been widely used in many fields, such as aerospace, automobile manufacturing, electronic appliances and so on. However, the defects in the die casting process, such as cold insulation, air bubbles, under-casting, etc., pose a challenge to product quality and production efficiency. In order to overcome these problems, CNC machine tool flexible unit (Flexible Manufacturing Cell, FMC) as an advanced manufacturing technology, is gradually being introduced into the die-casting production, in order to achieve more efficient, more flexible processing methods.

Overview of# #1. CNC Machine Flexible Unit

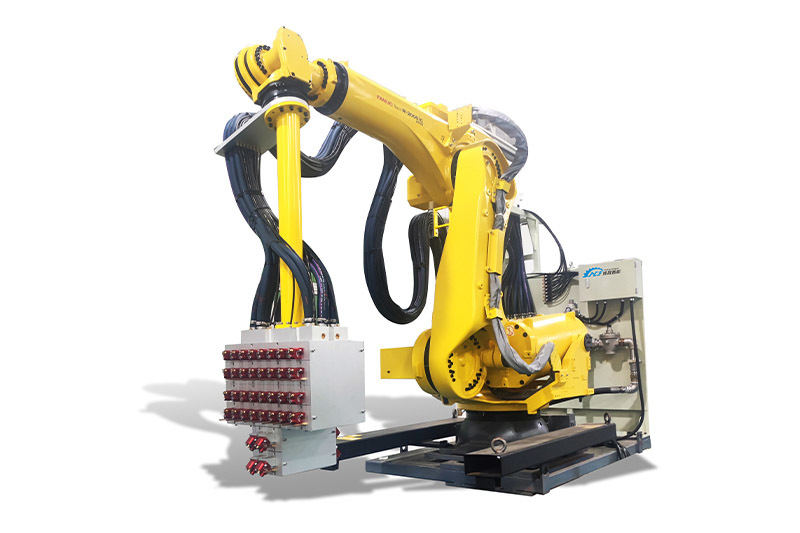

A CNC machine tool flexible unit is a simplified form of a flexible manufacturing system (Flexible Manufacturing System, FMS), which usually consists of one or more CNC machines, industrial robots, material handling systems, and control systems. It has a high degree of flexibility and adaptability, and can quickly adjust the production layout and process flow according to the processing needs of different products, and realize the efficient production of multiple varieties and small batches.

## Advantages of 2. CNC machine tool flexible unit in die casting

### 2.1 increase production flexibility

Die casting production often faces the challenge of many kinds of products and small batches. The flexible unit of CNC machine tools can easily cope with the processing needs of different die castings through its flexible programming and rapid mold change capabilities, realizing rapid production switching and significantly improving production flexibility.

### 2.2 to improve machining accuracy

Die castings are prone to dimensional deviations and surface defects during the molding process. The flexible unit of CNC machine tool adopts high-precision numerical control technology, which can accurately control cutting parameters, ensure machining accuracy, reduce subsequent processing volume, and improve product quality.

### 2.3 reduce production costs

By optimizing the production process and reducing manual intervention, CNC machine flexible units can significantly reduce production costs. At the same time, its efficient processing capacity also shortens the production cycle and improves production efficiency.

## Specific application of flexible unit of 3. CNC machine tool in die casting

### 3.1 mold processing

Die-casting die is a key component in die-casting production, and its quality directly affects the quality of die-casting parts. The CNC machine tool flexible unit can be used for precision machining of molds, including milling, drilling, tapping and other processes of cavities, cores, sliders and other components. Through high-precision processing, to ensure accurate mold size, smooth surface, to provide high-quality mold protection for die-casting production.

### Post-treatment of 3.2 die castings

Die castings often need to be deburred, polished, polished and other post-treatment processes after molding. The CNC machine flexible unit can be equipped with corresponding grinding and polishing machines to automate the processing of die castings. Through precise programming and real-time feedback adjustment, the processing effect is consistent, and the appearance quality and surface finish of the product are improved.

### 3.3 Defect Repair

The flexible unit of CNC machine tool can be locally repaired for defects such as cold isolation, bubbles and under-casting in the die-casting process. By accurately controlling the cutting parameters and tool path, the defect parts are accurately processed to restore the integrity and performance of the die casting.

##4. case analysis

An auto parts manufacturer introduced the flexible unit of CNC machine tool in die casting production. Through the application of this unit, the company has realized the rapid processing and precise repair of the mold, and significantly improved the service life of the mold and the quality of the die-casting. At the same time, the CNC machine tool flexible unit is also used in the post-processing process of die castings, which realizes automatic grinding and polishing, and improves the appearance quality and production efficiency of the product. In the end, the company's die-casting production efficiency and product quality have been significantly improved, and the market competitiveness has also been enhanced.

##5. conclusion

The application of CNC machine tool flexible unit in die casting production has brought revolutionary changes to the manufacturing industry. By improving production flexibility, machining accuracy and reducing production costs, the flexible unit of CNC machine tools provides strong technical support for die casting production. With the continuous advancement of technology and the continuous expansion of application fields, the flexible unit of CNC machine tools will play an important role in more fields and promote the development of manufacturing industry to a higher level.

Key words: